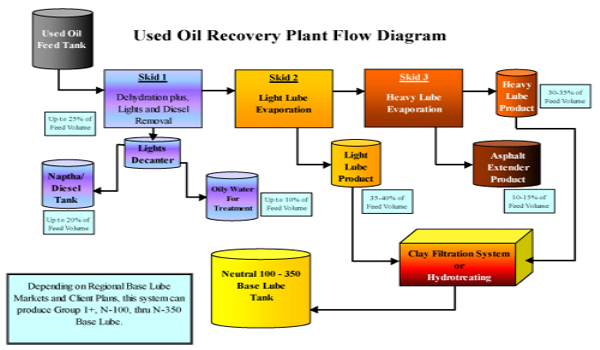

Used Lube Oil Re-Refinery System

We design and build systems which recover useable, clean lubricating oils and diesel fuel.

FLAG can give you the quickest turnaround time on fabricating these units at a great price. Each component is custom designed, manufactured to exact specifications, and is inspected to insure the highest standards of quality control in our workmanship. FLAG’s systems combine technologies which produce a superior product, without producing more waste which can damage the environment!

* Our systems are controlled by modern PC/PLC control systems and can function completely automatically;

* Our Systems are small & medium scale and modular;

* They are less expensive than most other types;

* Our multistage systems can deal with a large variety of feed oils;

Used oil can be re-refined over and over again and is subject to the same stringent refining, compounding and performance standards as virgin oil.

Adapted from existing crude oil refining technology for the used oil recovery sector, FLAG ETS is now offering Solvent Extraction either as a stand-alone lube polishing option to upgrade recovered oils (or VGO) to a Group I comparable base lube, or in combination with FLAG ETS’s state-of-the-art regenerative media lube polishing systems (LPS) to produce Group II comparable base lube.

The combination of FLAG ETS’s Solvent Extraction technology with our LPS technology produces a high quality Group II comparable base lube, without incurring the much higher costs and increased safety issues associated with hydro-treating.

FLAG ETS’s Solvent Extraction Process has been demonstrated to effectively improve the percent saturates, Sulphur level, color, stability, aromatics content, and odor of typical recovered oil by:

* Increasing the saturates by 3 – 5+%,

* Slightly decreasing Sulphur levels (though not below 300 ppm as a stand alone system)

* Dramatically improving oil color from ASTM 4.0 – 7.0 (medium to dark amber), down to 1.0 – 1.5 (light gold)

* Significantly enhancing base oil stability (no color deterioration or gum formation in storage)

* Effectively reducing PAH (polyaromatic hydrocarbons) content to BDL (below detectable levels)

* Markedly reducing odor (from the typical sharp burnt smell to a clean petroleum smell)

To facilitate environmental restoration, resource recovery and pollution reduction through innovative technologies and the design, construction, and operation of affordable state of the art liquid recovery and biofuel equipment.

FLAG ETS, LLC